Everything at Nivell has for decades revolved around how machinery is set up. Levelling machines up, securing them and isolating vibrations forms the core of our work.

It began in the 1970s with the setting up of standard machine tools. The focus at that time was fully on levelling using wedge shoes and a short time later was then broadened out to non-slip levelling elements.

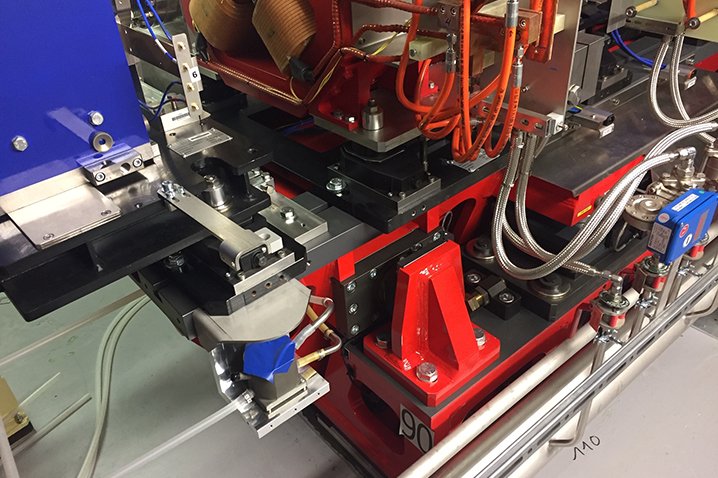

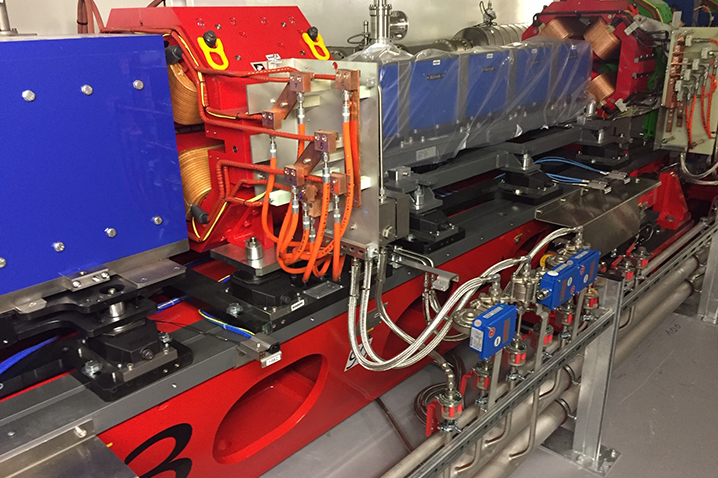

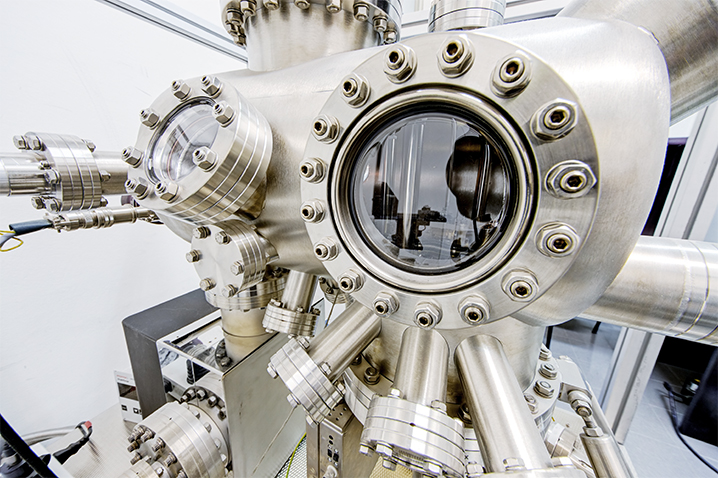

Today, a lot of companies from all sorts of industry sectors put their trust in us. Even when it comes to the very special requirements of large research facilities the specialists there build on our expertise – you will, for instance, find our set-up elements in the new european synchroton ESRF in Grenoble France, probably the most precise piece of equipment of this kind. Nivell’s wedge shoes also provide extreme precision and reliability to similar projects in the USA, Beijing China and Switzerland. And that’s just the start!

No matter at what point you currently are – whether you are at the start of a project or are facing unexpected challenges, feel free to get in touch. Our aim is to find the optimum solution for your application. Our decades of experience, coupled with our ambition to jointly master even complex matters, spurs us on.

Every machine makes different demands in terms of set-up. From rigid to sprung, from screw-fixed to free-standing, from roughly to precisely levelled, from light to heavy ... So it’s clear: Not every wedge shoe suits every application. Nor does it have to. Our technicians develop exactly the solution you need. In this way we are able to offer you extreme precision and reliability, even for very special requirements.

What we’ve already succeeded in doing:

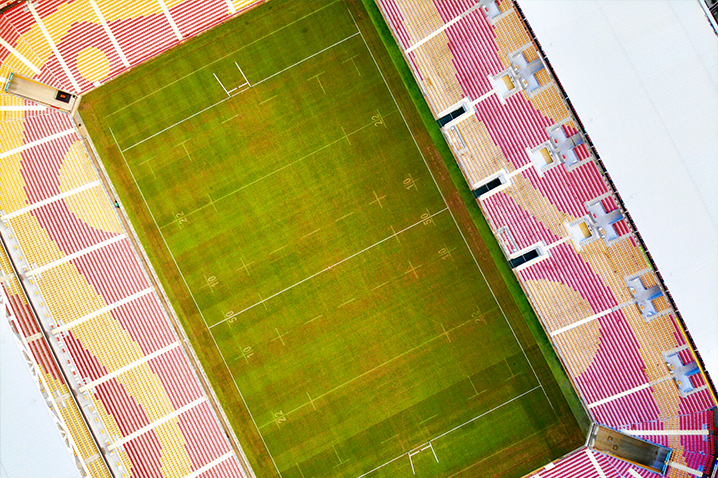

- Isolating a stadium roof's vibrations

- Regulating the particle accelerator of a large research establishment in France

- Developing a custom solution for hydroelectric power plants

- Developing a stable, high-precision levelling unit for large-format X-ray machines with 3D displays

- Developing a vibration damper for large machines

Special requirements demand special solutions.

However, not every new solution requires a completely new development.

If the customer wishes, our large, existing product portfolio allows us to fall back on a finished product that meets similar requirements and develop it further, depending on the customer's needs.

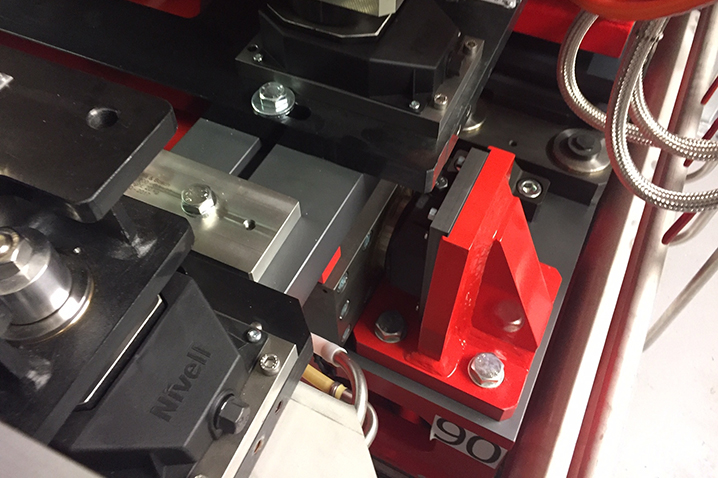

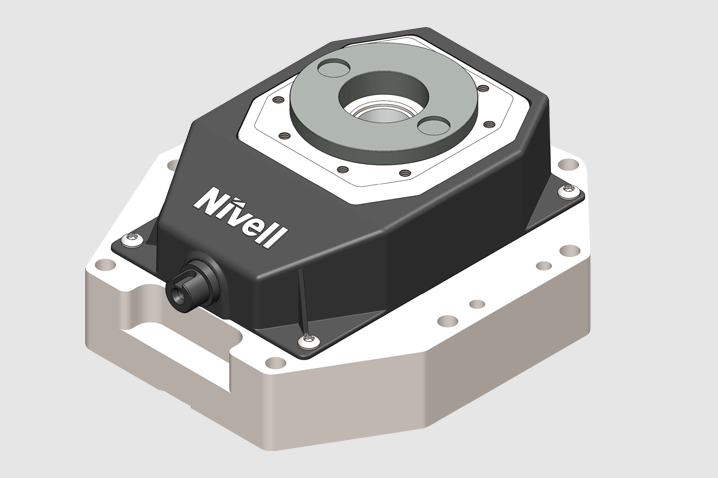

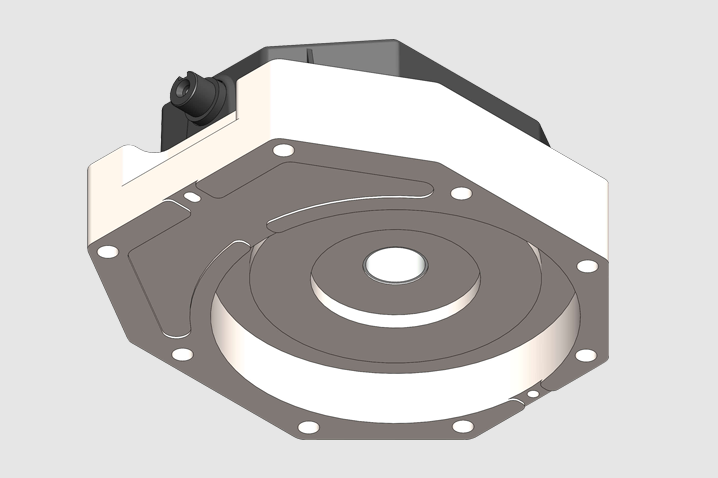

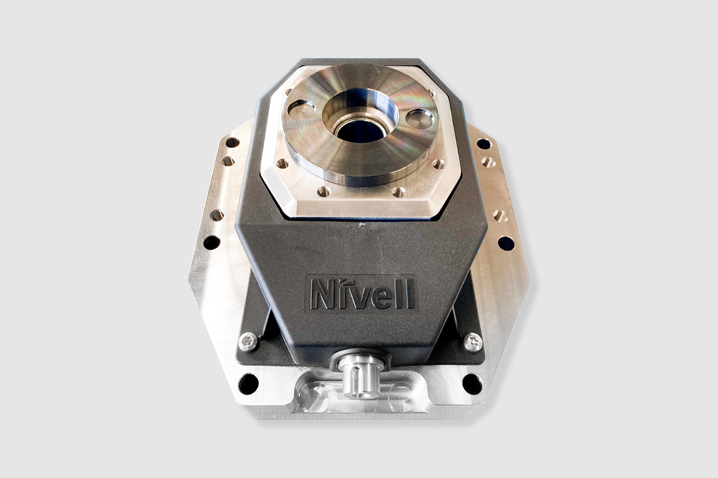

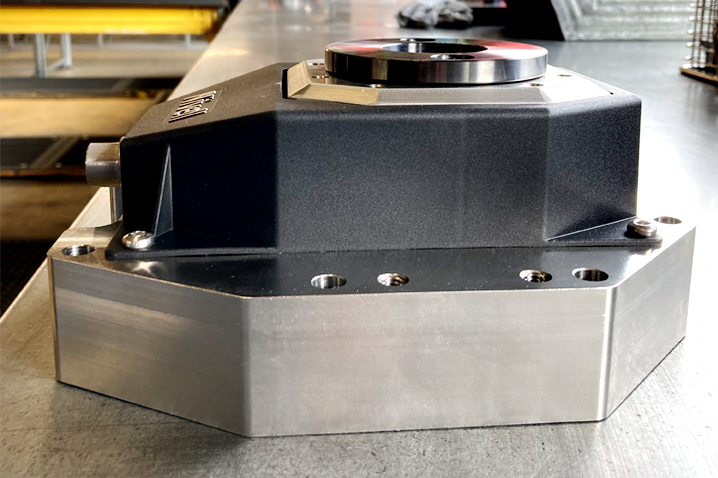

This new leveling wedge (see picture) was further developed from an already existing leveling wedge, so that it exactly meets the customer`s requirements.

Our in-house engineers check the customer's requirements and compare them with the requirements for our standard products.

A further development of a standard product often is more reasonable for the customer in many aspects.

Compared to a completely new development, both the time factor and the cost factor are significantly lower.

The end product is a completely independent product that is precisely tailored to the customer's requirements.